Article by SWAN Technical Support Officer, Alejandra Santos Rubiano.

As an Australian sugarcane grower or crop water manager, I’m sure that many questions come to mind when you’re considering how best to irrigate.

What is the best irrigation system to use? How much water should I apply to get the highest possible yield? How often should I irrigate? These are all questions that you might be pondering. So now, let me tell you there are no right or wrong decisions to be made regarding irrigation; as long as you use your resources effectively.

Let’s start from the beginning. As you may already know, Australia produces approximately 30 million metric tons of sugarcane per year, grown over 365,000 hectares. It is the second largest raw sugar exporter in the world, exporting more than 80% of its raw sugar[1].

This production is concentrated in the east coastline of Australia, from Grafton in northern NSW to Mossman in Far North Queensland. Throughout these regions, there is great variation in irrigation system selection and water availability. While overhead, drip and furrow irrigation systems are widely used across the sugar industry in Australia, the irrigation method selected varies depending on the region.

For example, in Queensland (where 95% of Australian sugarcane is produced), the most common irrigation system used is furrow irrigation. This system consists of a series of furrows that are designed with slopes of up to 3%, to allow water movement from the top of the field to the bottom. The water can be delivered to the top of the furrow by means of an open channel, a pipe or fluming, and moved through the field by gravity. Generally, an irrigation event will be completed once the water reaches the bottom of the furrow.

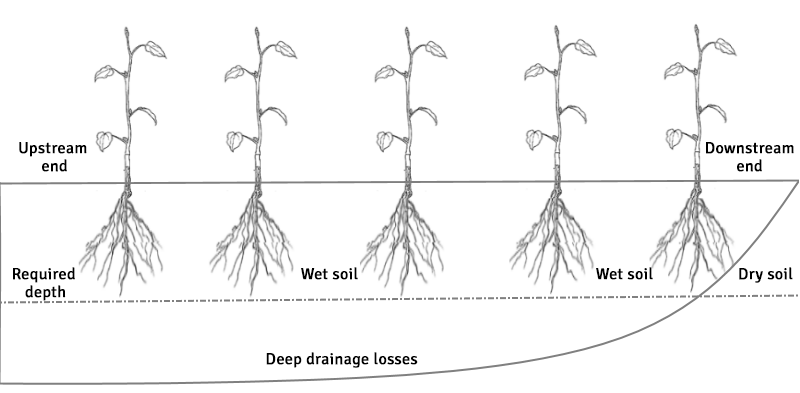

The initial equipment investment for this type of irrigation system is low compared to others. However, its application efficiency can vary from 30% to 90%, and there are 3 main factors that can directly impact on system efficiency: soil type, inflow and furrow dimensions. To understand this concept better, have a look at the following image.

Imagine you are looking at your field sideways. As you can see, the amount of water available to plants at the top of the furrow will be greater than the amount available to plants at the end of it.

Additionally, your soil type will determine the lateral soakage, how fast the water will infiltrate the soil, and how fast the water will move along the furrow. Furthermore, the inflow and furrow dimensions (especially the furrow length) will determine how many hours your irrigation event should last to enable the water to reach the bottom of the field.

All this sounds relatively straightforward, doesn’t it? All you need to do is to get your furrow and inflow right. Well let me tell you something: it’s not as easy as it may appear!

Every day, sugarcane farmers in Australia face these decisions and many are not even aware of the challenges. Some believe that just because the water has reached the end of the field, it was a good irrigation event. However, the situation is far more complex than that.

Some soils have poor lateral soakage, which means that even if the irrigation event has lasted for hours and the water has reached the bottom of the field, it is not available for the plants in the right proportions.

In North Queensland, for instance, it is common to find soils that have poor structure due to the amount of sodium present in them, which can significantly reduce the irrigation efficiency – especially in furrow irrigated crops. This is due to the water not moving laterally to the root zone and the runoff increasing. In cases like this, it is recommended to use pulse irrigation, which consists of irrigating your fields intermittently to let the water settle in the field while providing a more uniform wetted profile.

Moreover, in some farms, the furrow length is excessive, which means that the water never reaches the end of the field. So, keep in mind that for furrow irrigation, you need to have your parameters right in order to have efficient irrigation. The good news is that there is sugarcane irrigation software capable of modelling the water movement throughout the field to get the highest possible efficiency, based on each farm’s specific situation.

Always remember that the main challenge with this irrigation system is to reduce your deep drainage and runoff, while ensuring your crop is receiving the desired amount of water. One last thing! Do not forget that although recycle pits are often a solution for farmers to collect runoff water, if your irrigation system and practices are appropriate for your farm, you will never need to build one.

Other types of irrigation used in sugarcane are overhead irrigation and drip irrigation. Overhead irrigation includes lateral movers and centre pivots. These irrigation systems are low-pressure irrigation systems that consist of a series of spans with irrigation sprinklers that have an efficiency of approximately 75%, when used and designed adequately. They can be used in regions with variable soil types and conditions – but require a higher initial investment when compared to furrow systems. The overhead system characteristics, such as spacing, pipe size, and system capacity need a detailed design.

Moreover, one of the main advantages of this type of irrigation is that some of these systems can irrigate large areas continuously and can be set as mobile or fixed systems. However, the mobile units generally require more labour and/or machinery than the others. Overhead systems are used mainly in the Tablelands and southern sugarcane irrigated areas.

Now, let’s discuss drip irrigation in the sugarcane industry. Sugarcane growers often install sub-surface drip irrigation systems, which allows them to supply water directly in the root zone with efficiencies of up to 95%. These systems also allow farmers to irrigate as frequently as required, with no runoff and low water losses by deep drainage (when the irrigation design and management are adequate).

As with the overhead systems, sub-surface drip irrigation requires a high initial investment, consisting of a series of emitters located in tubes connected to the pipeline. The emitters are commonly pressure regulated, which ensures that the amount of water delivered to the crop is uniform, regardless of the distance from the water source.

It is worth noting that sub-surface drippers facilitate the use of machinery in the field, especially in the north Queensland region, where sugarcane is burned to be harvested afterward. However, it is important to consider that if the design is poorly done or if the system is not maintained properly (i.e. blocked emitters), sugarcane yields can decrease significantly.

All in all, each system has its advantages and disadvantages and depends on your specific situation to determine which will be the most suitable for your farm. Nonetheless, there are other aspects that are as important as your irrigation system and that are worth considering before each irrigation event. These aspects refer to when and how much you need to irrigate, and irrigation scheduling is what you need to address these questions.

As you may already know, it has been reported that in conditions where temperature and sunlight are adequate, the sugarcane growth is proportional to the amount of water that is being received by the crop. But do not get too excited! It is also known that excessive irrigation can decrease commercial cane sugar (CCS) content. This is because the plant needs to be subjected to some stress to store sugar in the stalk.

To know how much and how often you need to irrigate, you need to calculate your crop evapotranspiration (ETc). But what is that? Basically, it’s the amount of water that is being evaporated from the soil surface, plus the amount of water that your crop transpires.

The crop evapotranspiration is affected by the amount of water available, climatic conditions and crop type. A crop that was recently planted will not have the same ETc as one that it is about to be harvested, and a crop that is planted in Bundaberg will not use the same amount of water as a crop planted in the Burdekin.

To complicate things further, calculating the ETc for sugarcane can be more complex than calculating ETc for other crops. This is because sugarcane is planted throughout the year and can have multiple ratoons, which will affect your ETc. Thankfully, there is smart software available – such as SWAN Systems – that can model your crop growth, using real weather data and soil information. This allows you to not only calculate your crop evapotranspiration, but also to determine when and how much you should irrigate.

I hope I have given you a good overview of irrigation in sugarcane and the technology available to improve your irrigation practices. This is where fun begins! Go out there and discover what works best for your crop.

[1] https://www.agriculture.gov.au/ag-farm-food/crops/sugar#sugar-industry-assistance-and-reform